HOW WE

DO IT

OUR APPROACH TO BUILDING A STRUCTURAL GLASS EXTENSION

This page takes you through the complete process of delivering a high-performance structural glass extension, using a recent project on a listed property in Essex as an example. While every project has its own constraints, opportunities and technical challenges, the principles shown here reflect our core approach: precise surveying, thoughtful design, meticulous engineering and expert installation.

By following this real case study from first enquiry through to completed build, you’ll see exactly how we turn an initial idea into a fully engineered, beautifully executed glass structure.

PRE-CONSTRUCTION PHASE

Every project begins with whatever information the client has — sometimes a tender pack, sometimes a sketch, sometimes just a conversation.

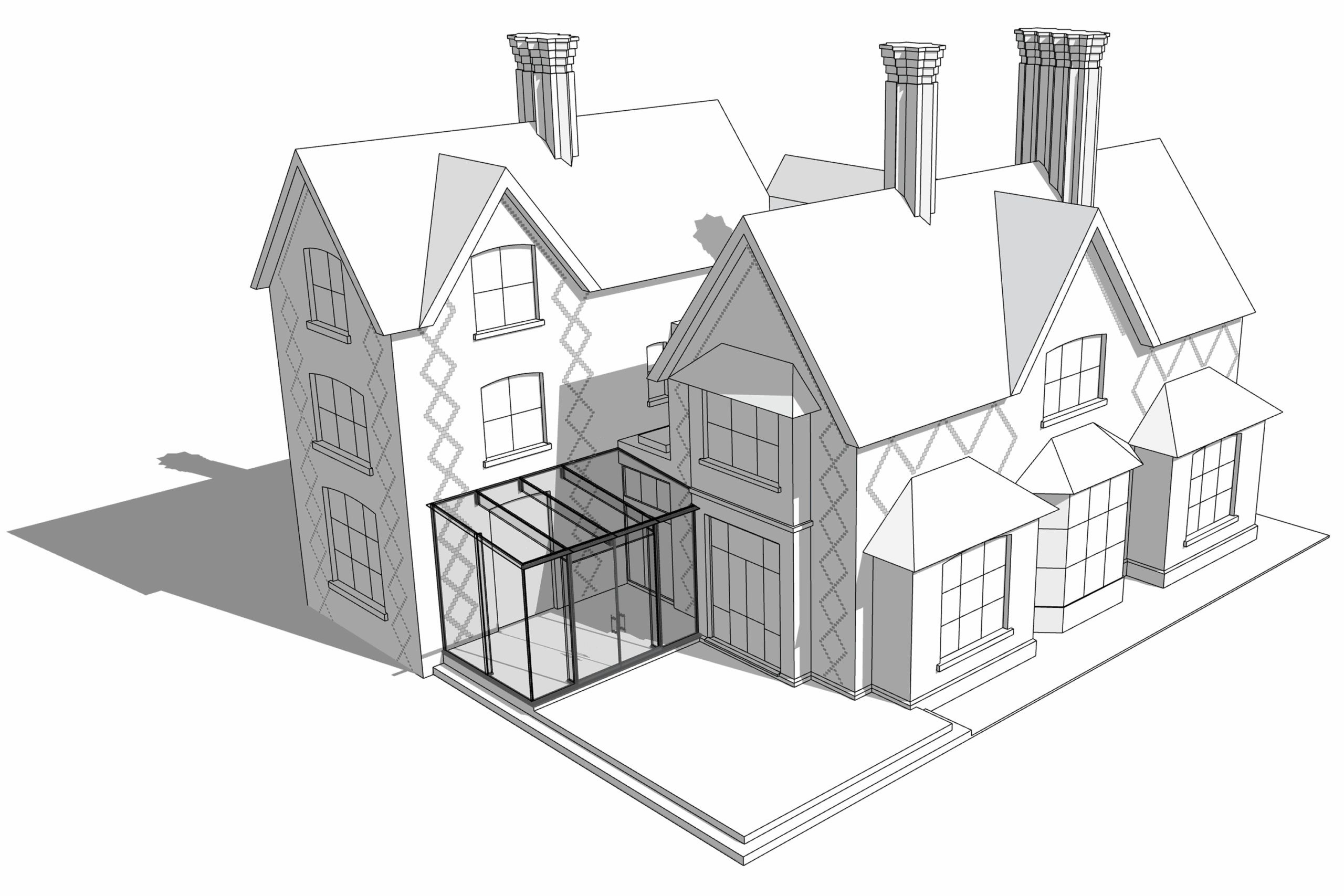

For this project, the clients architects provided early architectural material outlining their desire for a frameless structural glass extension to match the footprint of their existing conservatory.

Early architect’s drawing outlining the client’s initial concept for a frameless structural glass extension.

We then carried out an initial survey of the listed vicarage, reviewing access, structural conditions, orientation and planning restrictions. Because the building was listed, all connecting points — especially at roof level — had to align with existing lead flashing chases.

This meant that from the very beginning, millimetre accuracy would drive every decision.

DESIGN PHASE

This stage is where we differentiate ourselves: through precision scanning, point-cloud modelling, engineering accuracy and visual clarity. The following image sequence shows how the design evolved.

A) LASER SCANNING AND INITIAL CONCEPTS

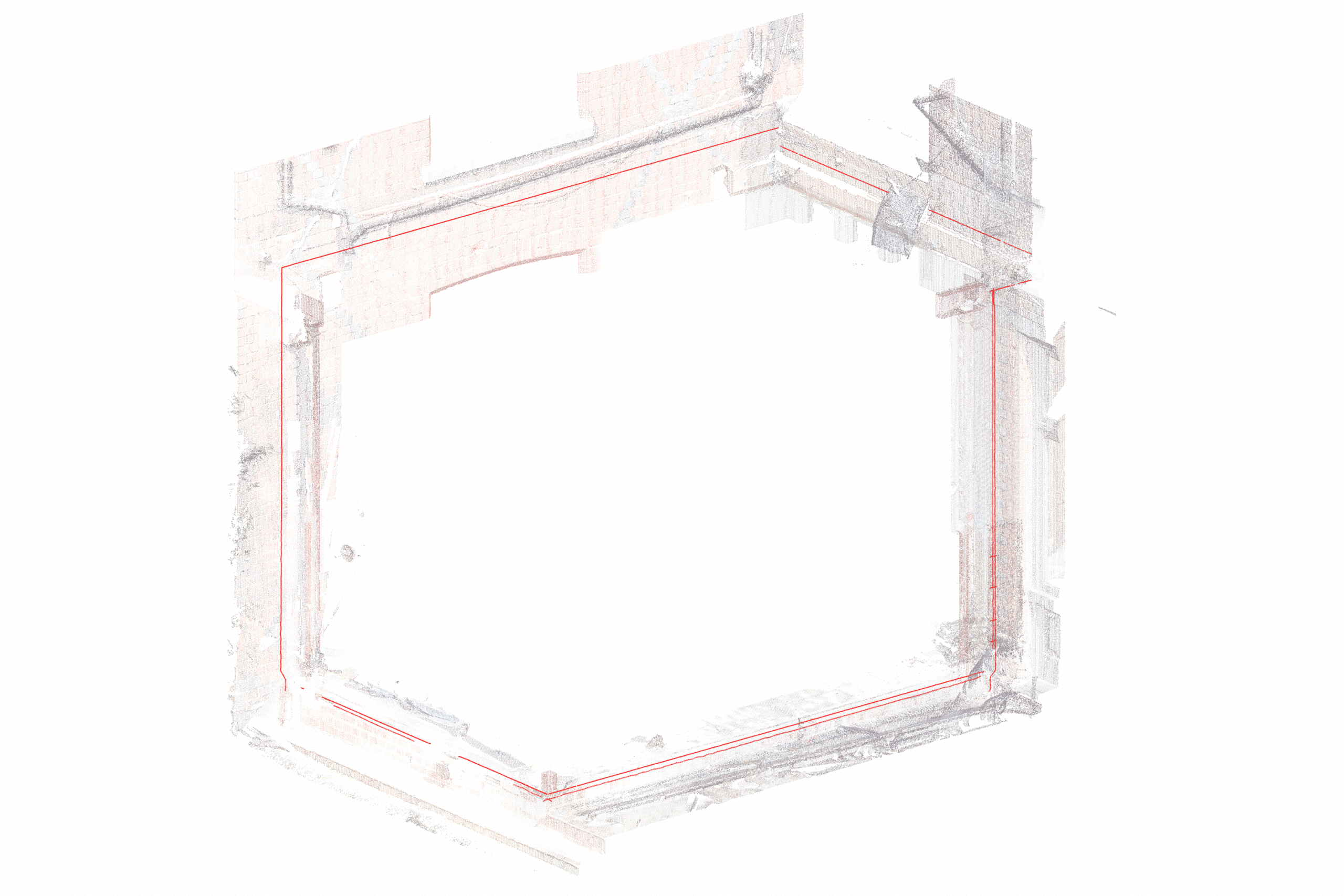

A full 3D laser scan captured millimetre-accurate data of the listed vicarage before design work began.

Concept sketch derived directly from the point-cloud survey, exploring the first design proposals for the glass extension.

Early visualisation showing how the new structural glass extension would integrate with the existing building.

B) INTEGRATING THE NEW BASE AND EXISTING STRUCTURE

The old conservatory was removed, and the builders constructed a new base according to our specifications.

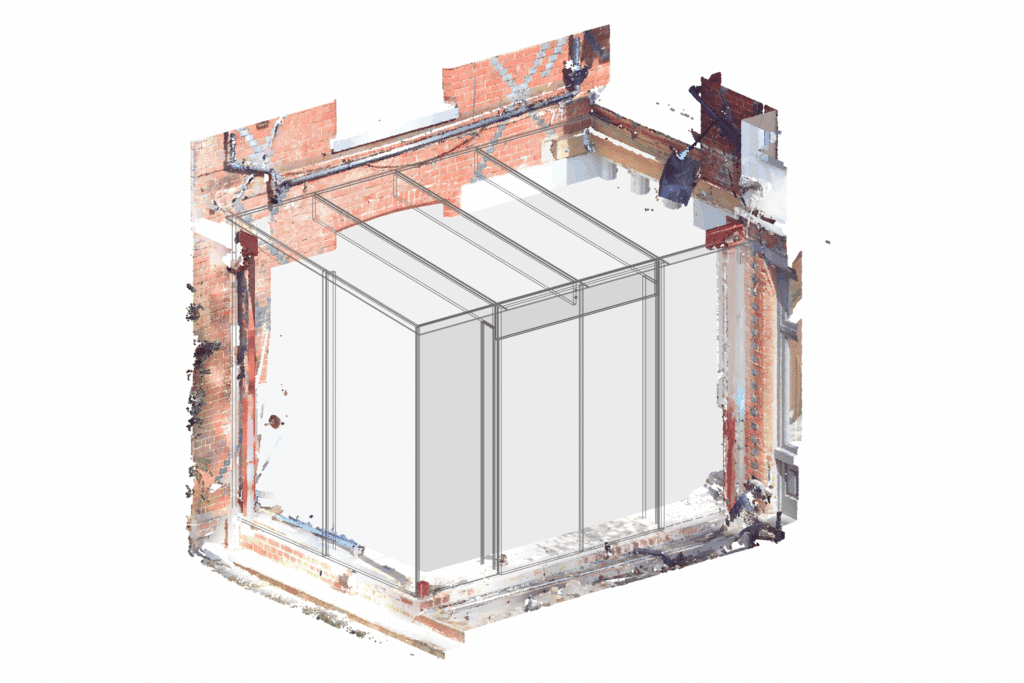

We then returned to site for a second 3D scan — a crucial step for ensuring the new structure aligned perfectly with the listed building fabric.

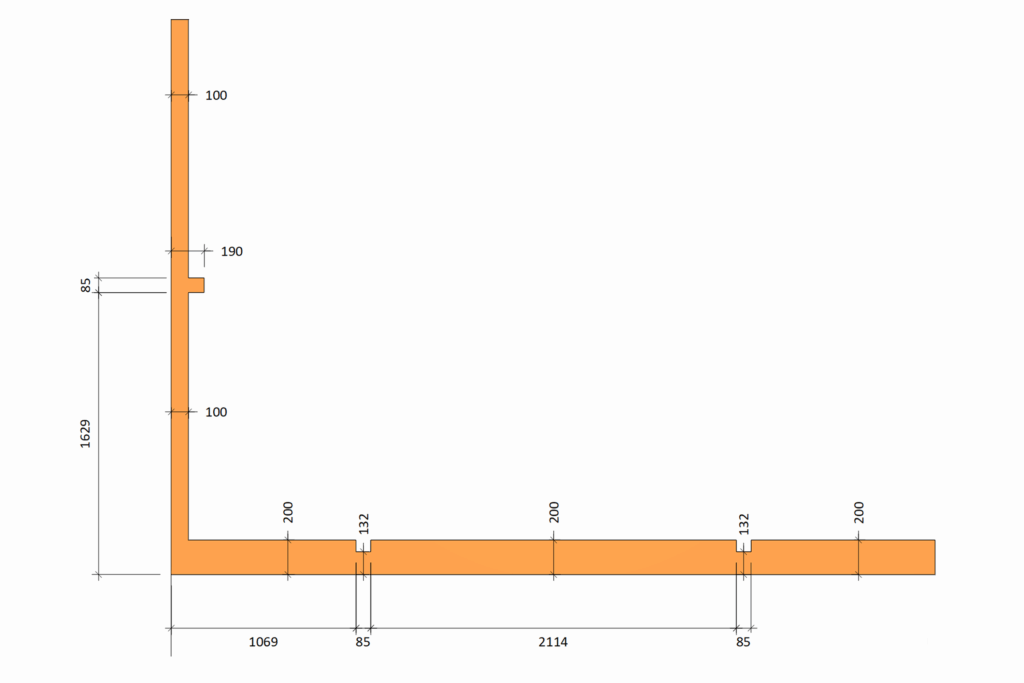

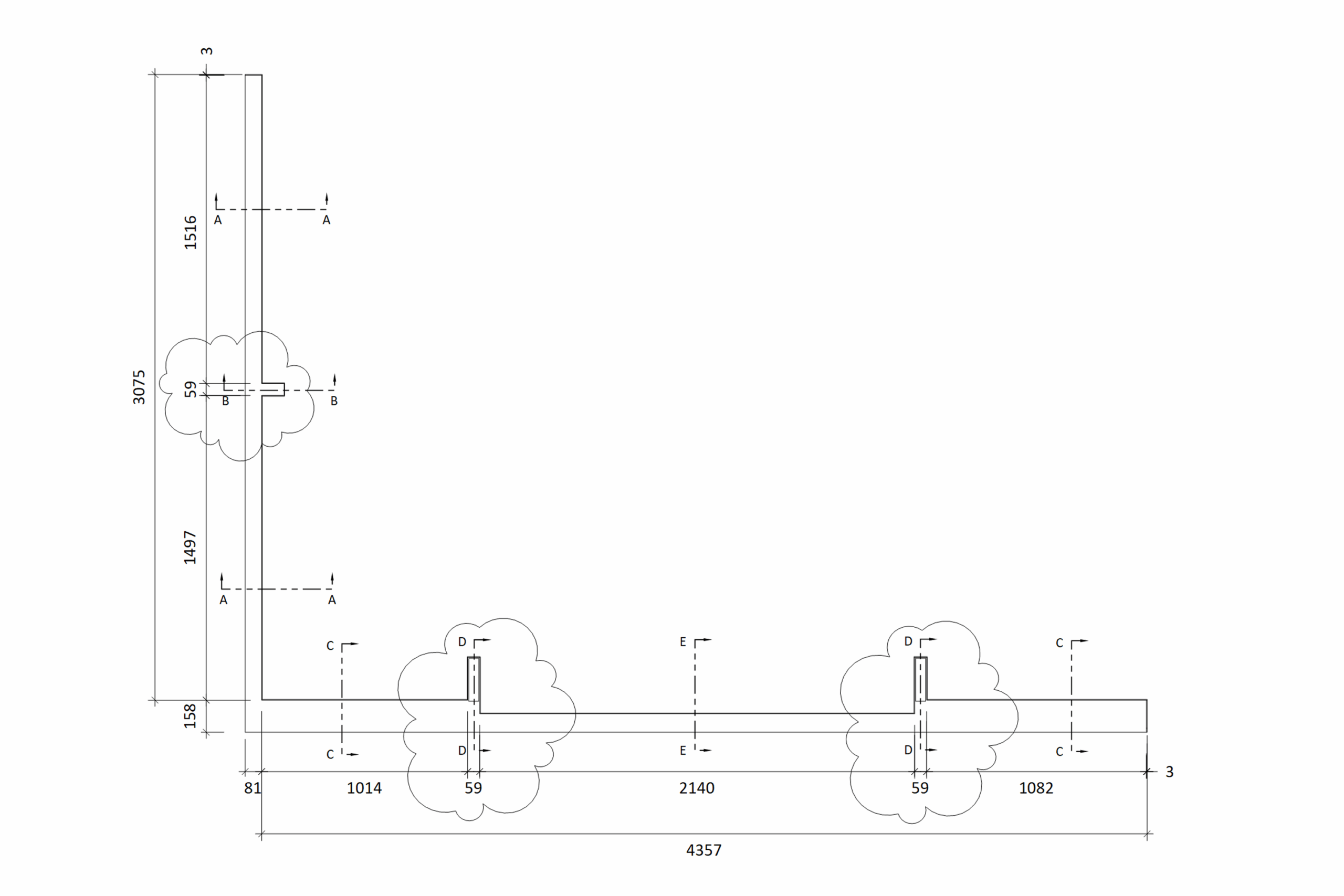

Dimensioned drawing issued to the builders, specifying exact footprint and upstand heights for the new structural glass extension.

The original conservatory removed and the new base constructed to our precise design specifications.

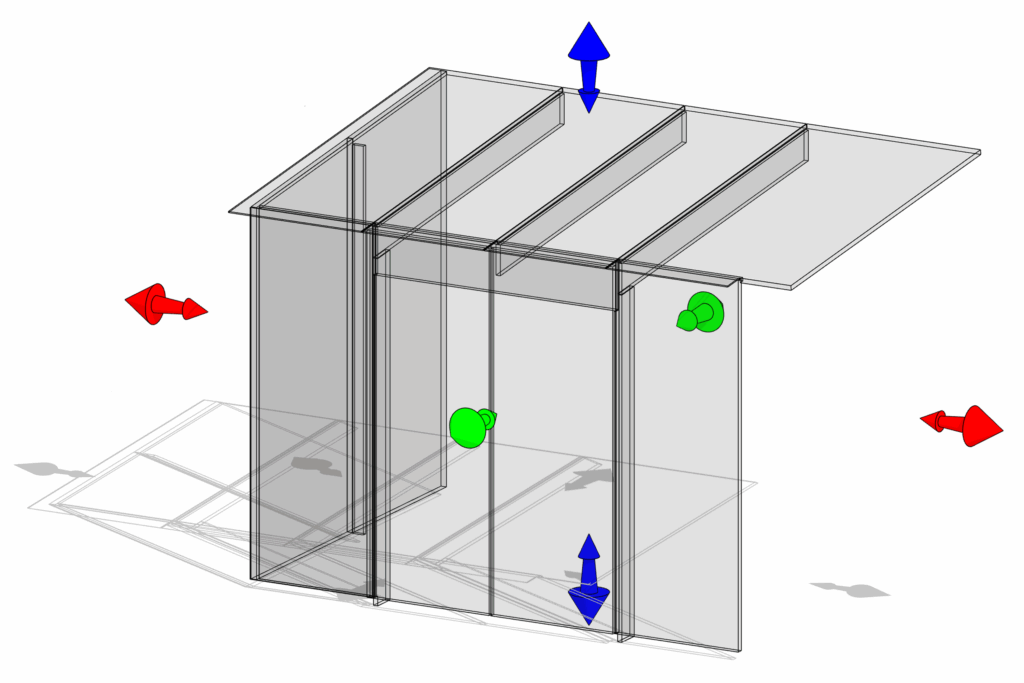

A follow-up 3D scan capturing both the newly built base and the existing structure, overlaid with the proposed glass units.

Section lines generated directly from the point-cloud mesh, ensuring each glass junction matches the existing building perfectly.

C) FINAL ENGINEERING AND FABRICATION

These final drawings are where every millimetre is verified and every component is engineered.

For listed buildings — especially those with complex interfaces like old lead chases — this precision is essential.

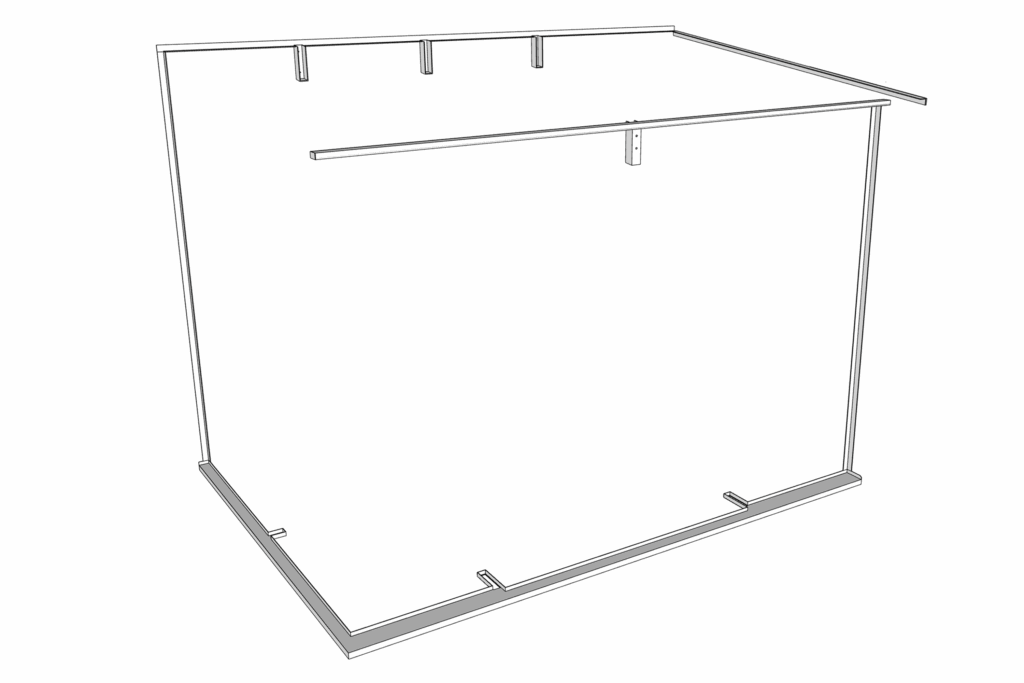

Isometric view of the supporting metalwork designed to carry the structural glass roof.

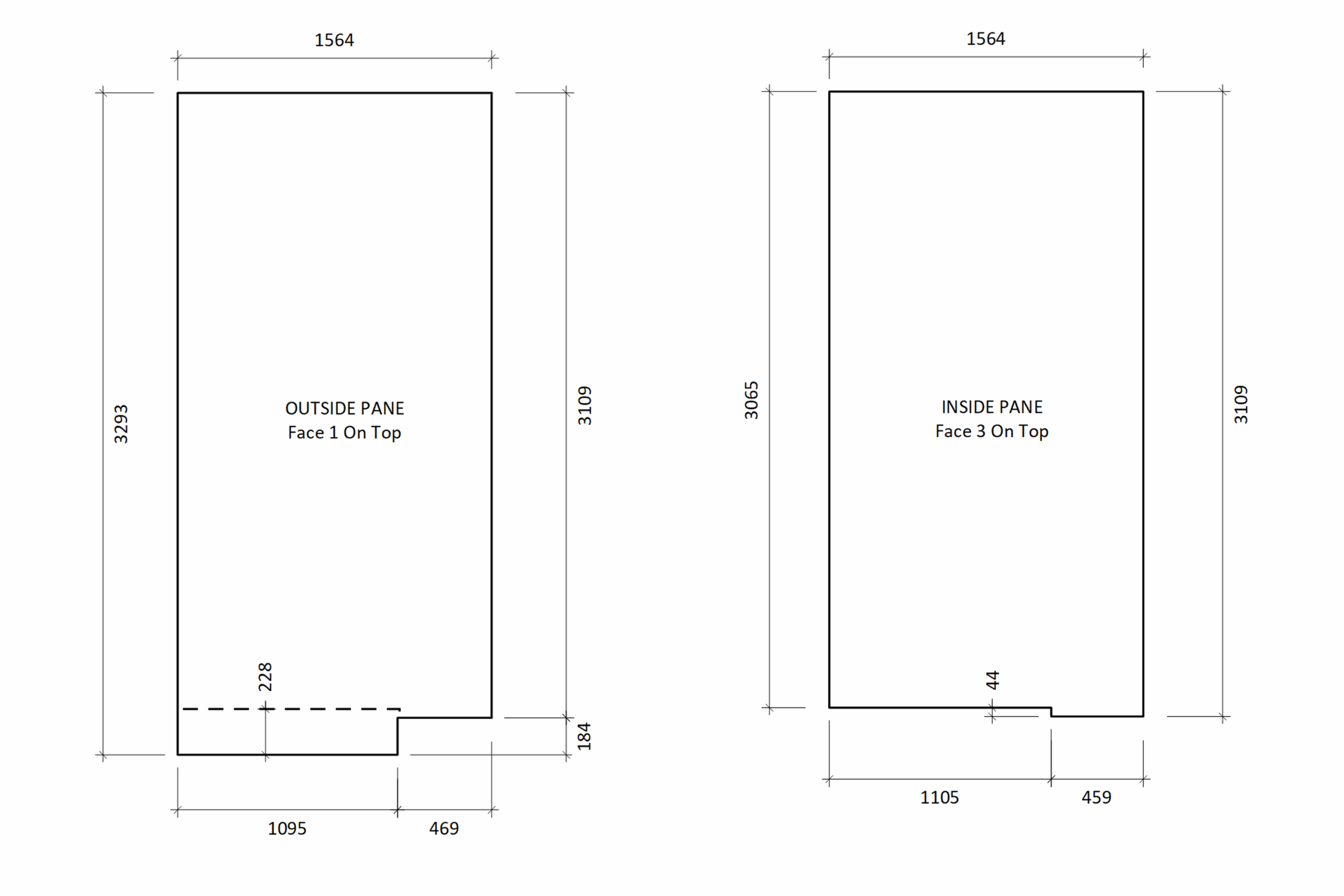

Detailed pressing fabrication drawing confirming exact measurements and interfaces before production.

Front elevation drawing showing the bi-parting minimal-sightline sliding doors within the final engineered glass configuration.

Technical drawing illustrating the precision required for each structural roof panel.

Isometric drawing showing the final engineered configuration of the frameless structural glass cube.

CONSTRUCTION AND INSTALLATION PHASE

Exact execution on site, culminating in a seamless, frameless glass cube.

Once fabrication was complete, installation began. Large structural glass units, roof beams and minimal-sightline sliding doors were brought to site and fitted using specialist lifting equipment.

A structural glass roof panel being lifted into position using specialist lifting equipment.

The structural glass extension under construction, with roof, beams and vertical glass panels being installed.

A bright, modern breakfast room with uninterrupted garden views thanks to high-performance structural glazing.

A seamless contemporary glass addition fully integrated with the listed vicarage.

The completed frameless glass extension, featuring ultra-slim sliding doors, solar control and low-iron structural beams.

THE RESULT

A Bright, Seamless Breakfast Room That Respects the Building’s Heritage.

The finished glass extension fits the exact footprint of the previous conservatory but transforms the space entirely.

Thanks to low-iron laminated beams, a frameless glass roof, minimal-sightline sliding doors and advanced thermal + solar control glazing, the homeowners now enjoy a bright breakfast room with uninterrupted garden views — all while maintaining full compliance with the property’s listed status.